При эксплуатации крюка и каната крана в условиях высоких температур они напрямую или косвенно подвергаются циклическому воздействию интенсивного тепла. Эти суровые условия могут повлиять на прочность металлических компонентов, что приводит к изменению свойств их материалов, структуры и физических характеристик.

По мере ускорения индустриализации условия эксплуатации специального оборудования становятся всё более сложными. Для решения этих задач были разработаны высокотемпературные электрические краны LDG.

Основные параметры высокотемпературного электрического однобалочного крана ЛДГ

| Parameter | Value Range | Description |

|---|---|---|

| Rated Lifting Capacity | 1–16 t | According to metallurgical standards, the lifting capacity of single girder cranes must not exceed 16 tons. |

| Span | 7.5–28.5 m | Limited by the span dimensions of the workshop. |

| Lifting Height | 6 / 9 / 12 m | In high-temperature environments, a safe distance (≥2 m) between the hook and the heat source must be maintained. |

| Duty Class | A3–A6 (light to medium duty) | For single girder cranes used to handle molten liquid metal, duty class is designed to A6 to enhance structural fatigue resistance. |

| Ambient Temperature | ≤ +50 °C | The distance from the heat source and the duration of continuous high temperatures should be specified. |

Характеристики высокотемпературного электрического однобалочного крана LDG

Structural Design

The welds between the web plate and flange plate adopt full penetration welding. Post-weld heat treatment is applied to relieve stress and prevent deformation under high-temperature conditions.

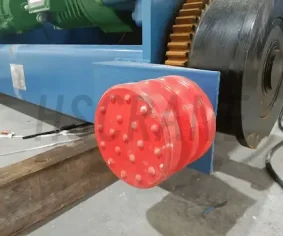

- Thermal Insulation Measures

The underside of the main girder and the outer sides of the end girders are lined with aluminum silicate fiber felt for thermal insulation.

Key components such as motors and gearboxes are equipped with detachable thermal insulation covers to protect them from heat radiation damage.

Key Components Upgraded for High-Temperature Resistance

| Component | Standard LD Configuration | LDG High-Temperature Configuration |

|---|---|---|

| Motor | Standard motor | High-temperature motor (H-class insulation), built-in temperature sensor (overheat alarm), protection class IP54 |

| Wire Rope | 6×19+FC standard wire rope | 6×37+IWR wire rope with metal core, coated with high-temperature-resistant grease |

| Wheel Set | Standard quenched steel | High-strength quenched steel, surface hardness ≥HRC55 to prevent softening under high temperatures |

| Electrical System | Standard distribution box | Explosion-proof temperature-controlled distribution box; cables made of high-temperature-resistant silicone rubber |

В чем разница между высокотемпературным электрическим однобалочным краном LDG и стандартным электрическим однобалочным краном LD?

| Comparison Item | Standard LD Electric Single Girder Crane | LDG High-Temperature Electric Single Girder Crane |

|---|---|---|

| Ambient Temperature Range | -20 °C ~ +40 °C | ≤ +50 °C |

| Motor Insulation Class | Class B | Class H, with temperature protection |

| Manufacturing Cost | Baseline cost | 30%–50% higher cost (due to thermal insulation system and high-temperature-resistant components) |

| Typical Failure Risk | Motor overload (more likely in high-temperature environments) | Deformation of main girder caused by failure of thermal insulation layer |

How to Select a Suitable LDG High-Temperature Electric Single Girder Crane

Determining Core Parameters

- Lifting Capacity

Include both the weight of the materials and the lifting devices.

- Span and Lifting Height

Determine based on the column spacing of the workshop and the height of heat sources.

- Duty Class

For high-temperature workshops, choose between Class A3 – A6.

High-Temperature Adaptability Configurations

| Component | Key Requirements |

|---|---|

| Main Girder | Equipped with a thermal insulation layer at the bottom to prevent damage from high temperatures. |

| Motor | Insulation class H, protection rating IP54. |

| Wire Rope | 6×37+IWR wire rope with metal core, coated with high-temperature-resistant grease. |

| Electrical System | Silicone rubber cables; control cabinet fitted with a temperature-controlled fan. |

Configurations for Special Operating Conditions

- High Temperature + Dust

Add high-temperature-resistant dust covers.

- High Temperature + Corrosion

Apply epoxy zinc-rich primer and fluorocarbon topcoat to metal surfaces.

- High Temperature + Explosion-Proof

Comply with ATEX standards; motor with Ex d certification.

Industry Application Case

Continuous Casting Workshop of a Steel Plant

Working Conditions:

Located 5 m from the continuous caster, ambient temperature 50 °C, used for lifting cast billets (lifting capacity: 16 t; span: 22.5 m).

Configuration:

Model LDG-16t-22.5m-A5, equipped with a 50 mm thick thermal insulation layer at the bottom of the main girder and a motor with forced air cooling. The crane has been operating reliably for 5 years.